Circular Gears

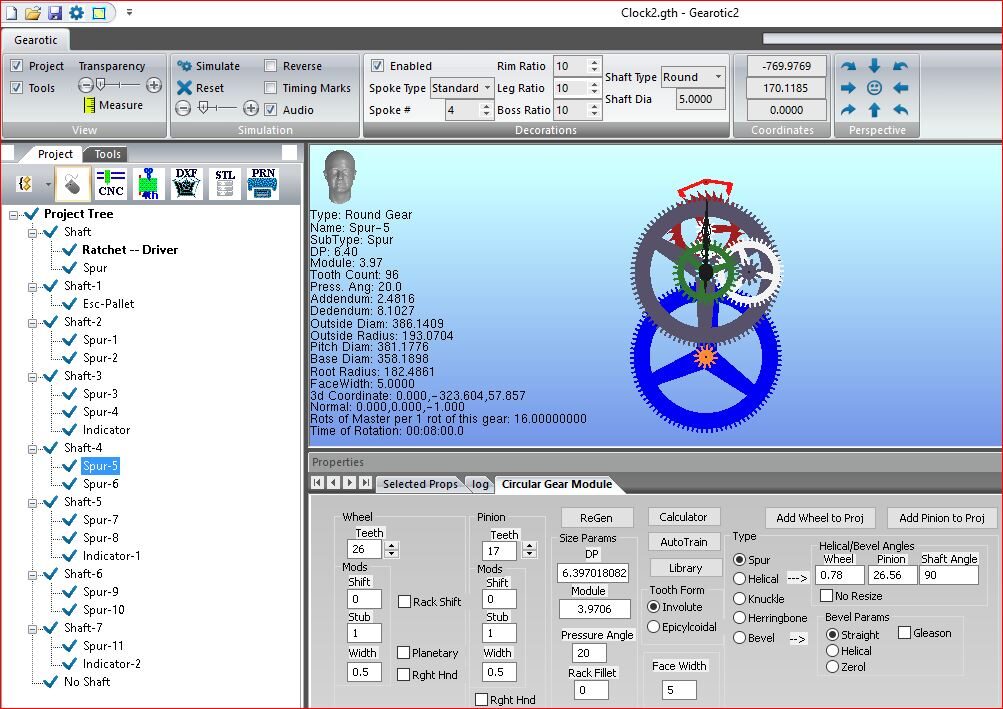

Gearotic CAD Project Screen

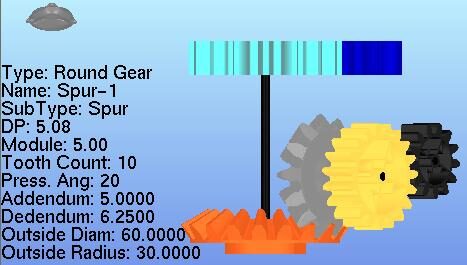

Within the Circular gear module of Gearotic CAD, a wide variety of gear type exist, that may be generated to correspond to user requirements. Software supports tooth formation for spur gears, helical, herringbone, bevels, and our very own knuckle gear for those 3D printers. Of course all gears fall within the ISO specs of that gear by default, but additional tools exist should slight tweaking be required to help mate new with very old gear design, non ISO standard. Gearotic CAD can vary the tooth form to go from involute to epicycloidal, and offers an offsets too. A series of adjustable parameters exits for each type, allowing full configuration of your gear including ring or planetary gear.

Inside Gearotic CAD, the Circular Gear Module basically enables the tool drawing platform to generate any circular gear. This module becomes a fundamental section and ability of Gearotic CAD in what it does and can do.

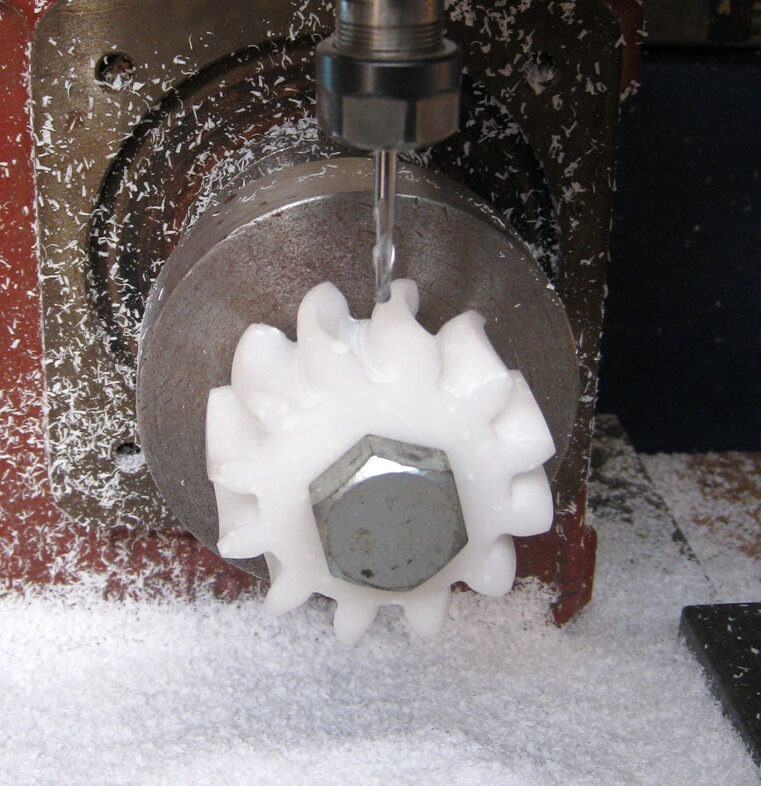

Helical or Bevel form gears can be outputted from Gearotic CAD as Straight, Helix or Zerol formats. Additionally we offer the Herringbone and Knuckle gear for you to play with too. These types of gears can be exported as STL’s for printing, real simple and easy. However, it only becomes possible to mill these type of gears with a 5 axis milling tool. We have however found a way if you make the blank, to do it using only 4 axis. I strongly suggest you visit GearHead Forum for more info on this technique, but it does work.

The creation of Planetary gears inside Gearotic CAD is possible, however a rule exist to be possible. Rule is, you must select a larger number of teeth on the primary outside wheel, in order to have enough clear distance to properly mesh the inner pinion wheel throughout. Planetary gears are used everywhere these days in design and functionality, and offer through Gearotic CAD a huge variety.

Gearotic CAD’s Circular Gear module supplies users with necessary tools to design gears defined in this category. Designs may consist of spur gears, planetary, helical, herringbone, bevel and our very own knuckle gear. Our simple to use front end design allows a gear to become a 3d object once the “Add Wheel To Project” or “Add Pinion To Project” gets pushed. This creates and implements the gear within Gearotic as a simulation object and gets added to the “Project Database”, Simply repeat the process to design your own gear train and all gears inside can be individually analysed from that point forward. A few helpful features also exist in the software. If you are adding or meshing a gear on to another gear, the gear placement screen will become active. It will draw a circular ring around the gear you’re adding a gear to, displaying the shaft centerline placement to help visualize what’s happening. You may then use your mouse to rotate the gear around until you are satisfied with placement, click once more to drop and lock in place. All of our gears are proper involutes using standard industry formulations with adjustable overrides. We invite you to review video’s made, be aware that the look of Gearotic platform may have change over time as it continues to develop , which isn’t important, what is important is to know how the gear gets generated and becomes part of Gearotic project, which in return remains the same as in newer revisions. Viderer feugiat at pro, mea aperiam

All rights reserved to: Gearotic Motion CAD

Email: support@gearotic.com Nova Scotia, Canada